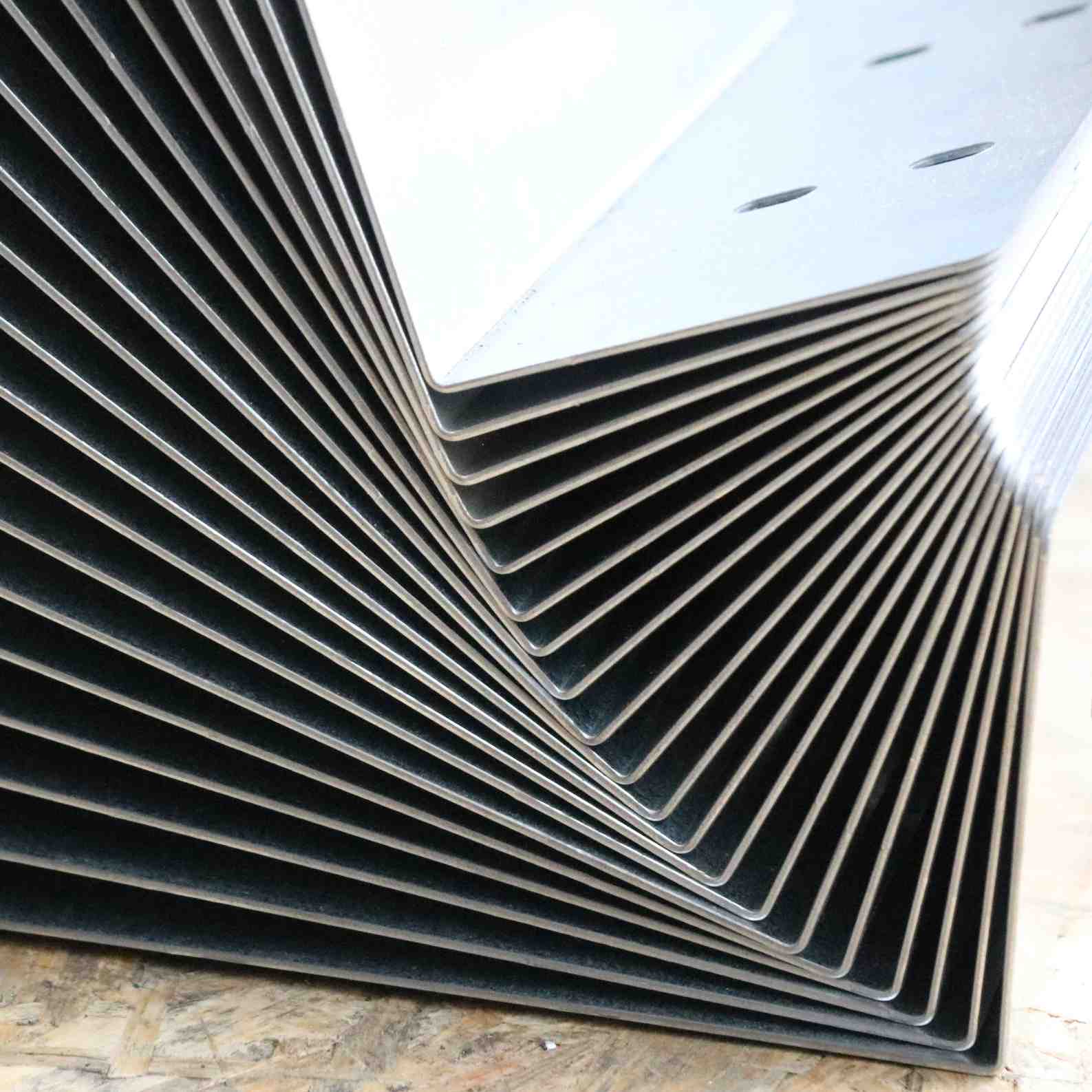

CNC Bending

CNC Bending Machine For Sheet Metal

We are the leading manufacturer of CNC Bending and also provide CNC Bending Services in Manesar, Gurugram. CNC bending machines can handle a wide variety of metals, including steel, aluminum, brass, and copper. The machines use various tools, such as punches and dies, to apply force to the metal and bend it into the desired shape. The computer program ensures that the bending is done with precision and accuracy, so that the final product meets the required specifications.

CNC bending is commonly used in the manufacturing of metal parts and components for various industries, including automotive, aerospace, and construction. The process allows for the production of complex shapes and angles with high precision and consistency, which is essential for many applications

As a CNC bending services provider, Sachin Steel Enterprises have a team of skilled technicians and state-of-the-art equipment to provide high-quality bending services to their customers. They can work with customers to create custom designs and produce metal components to the required specifications.

When sheet metal is reshaped from a flat form, it is done so using a method known as CNC bending, also known as CNC shaping. Almost any component design may be produced using CNC bending technology. A simple illustration of this would be to bend a flat piece of metal at a 90-degree angle to create a “L”-shaped bracket.

‘Computer numerically controlled’ is referred to as CNC. In other words, computer software converts your design into code, or a series of numbers, and it is this code that governs the machinery used for bending. CNC press brakes are the tools used for CNC bending. They can change sheet metal that is a few centimetres to several metres long in size.

Benefits of CNC bending technology